Since the LVDT core rod assembly is cantilevered at one end, it can be susceptible to vibration dampening challenges. Depending on the amplitude, it may warrant hard mounting, a spring or electronic filtering.

LVDT Core Extension Rod Hard Mounting: If the vibration is severe and you can visually see the core rod moving side to side a mechanical solution may be required. In this case, making the Internal Diameter (ID) bore of the LVDT to the OD of the core space smaller using a PTFE or Nylon washer that has an OD that is about 0.25mm smaller OD compared to the bore of the LVDT attaching it to the threaded end of the core opposite the core extension rod. Thus reducing clearance and dampening the vibration.Another method would be to add reducing bushings to each end of the LVDT bore. Attaching the bushing can be done by adhesives suitable for the application, an interference fit (press fitting the bushings into the bore or mounting them in a collar that conforms to the OD of the LVDT housing and with an ID that accommodates the OD of the LVDT core extension rod leaving a suitable fit for free reciprocal movement of the extension rod.

Spring mounting The LVDT Core Extension Rod: A spring can be mounted between the moving assembly and a fixed point to help reduce vibration but also can exacerbate the problem with harmonics and transients. Success in reducing the vibration depends on the amount of energy / acceleration present in the core rod assembly and matching the correct spring rate and consideration of the effect on the mechanical assembly.

Signal Conditioning Filtering: If higher frequency vibrations are seen in the output then you can filter the signal output from the LVDT signal conditioner. To do this you will have to characterize the output to determine the correct filter values. Typically this is the preferred solution since it done with electronics.

Elements to consider:

- Noise Characterization

- Valve dithering (oscillations)

- Electronic filtering

- Mechanical dampening

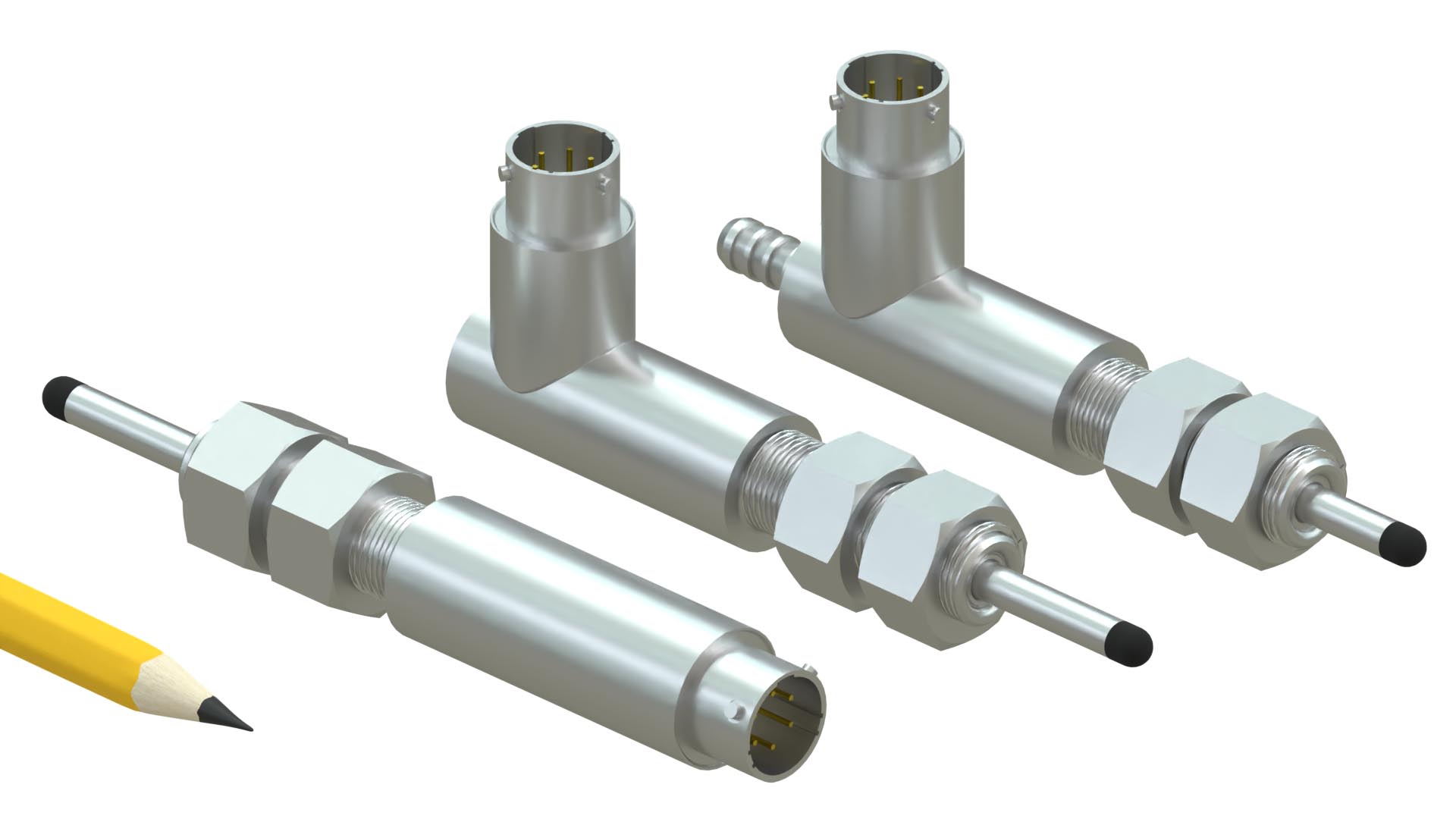

Click here to see our LVDT Sensors:

Additional pricing or technical questions?

Categories

Date

Page Categories